Hydraulic Garbage Compactor

Garbage Truck For Sale

The Hydraulic Garbage Compactor Truck is engineered to deliver powerful and efficient waste collection services across a wide range of urban and industrial environments. With its high loading capacity, advanced hydraulic compression system, and durable ST-52 steel compactor body, this municipal garbage collection vehicle stands out as an essential solution for modern waste management operations carried out by municipalities and private cleaning service providers.

🔧 General Features

The vehicle body is manufactured from high-strength ST-52 steel, featuring a 5 mm thick floor plate and side walls ranging from 4 to 6 mm depending on the model. This robust structure ensures long-lasting performance under heavy-duty conditions. The body is supported by a solid subframe mounted onto the chassis, maintaining vehicle stability during both transport and unloading.

The rear-integrated compaction system allows optimal use of the internal volume, enabling waste compaction even while the vehicle is in motion. Depending on the type of waste, the compaction ratio ranges between 1:4 and 1:6, maximizing the hauling efficiency.

The system is compatible with various truck chassis equipped with 4×2 or 6×4 drive systems. Capacity options range from 8 m³ to 22 m³, and the system can be configured to integrate with commercial truck models such as Ford Trucks, Mercedes-Benz, MAN, Iveco, and Isuzu. This versatility makes it suitable for both metropolitan municipalities and district-level sanitation operations.

🛠 Hydraulic System and Working Mechanism

At the core of the Hydraulic Compactor Garbage Truck lies a powerful and reliable hydraulic system. The hydraulic pump used in the vehicle offers a flow rate ranging from 36 cm³/min to 90 cm³/min and operates at up to 1500 rpm. This ensures a safe and continuous compaction process even under high pressure. The system maintains stable performance across all functions, including container lifting and rear compartment compaction, with an operating pressure between 170 and 190 bar.

The hydraulic oil requirement is supported by a reservoir with a capacity ranging from 80 to 240 liters, depending on the vehicle model. This large tank allows the system to operate for extended periods without overheating or loss of performance. The hydraulic actuator mechanism consists of a total of 9 cylinders, although this number may vary based on the type of container lifting system integrated into the truck.

The entire hydraulic setup is driven by a PTO (Power Take-Off) unit, which can be adjusted to operate between 750 and 1500 rpm. This unit transfers engine power to the hydraulic pump with high energy efficiency. The compaction cycle completes in just 20 to 35 seconds depending on waste density, ensuring faster operations and maximizing efficiency on the field.

🔄 Container Lifting Mechanism and Discharge System

The Hydraulic Compactor Garbage Truck is equipped with a modular and robust lifting mechanism capable of handling containers of various sizes with ease. Designed to work seamlessly with both plastic and metal bins, the system supports standard 120, 240, 770, and 1100-liter containers. Optional versions are also available for lifting large-capacity containers up to 2500 liters.

The lifting mechanism is compliant with DIN 30700 and EN840 standards, making it suitable for handling 120 and 240-liter plastic bins, as well as 0.4, 0.8, and 1.1 m³ metal containers. Depending on operational needs, optional lifting systems such as an arm-type lifter (for 3 to 8 m³ containers) or a hydraulic motor-powered cable system can also be integrated.

With intuitive controls, the operator can lift, empty, and return containers efficiently and safely in a single action. The hydraulic cylinders in the system lift the container at a vertical angle, ensuring complete waste discharge into the hopper. This design reduces manual effort and minimizes time spent per operation. The lifting height varies between 1000 and 1400 mm, providing ergonomic usage. Optionally, a wastewater tank with a capacity between 80 and 150 liters can also be installed to support hygiene and environmental standards.

The discharge operation is powered by high-performance cylinders integrated into the rear door system. Once the rear door is opened, compressed waste is ejected from the hopper under hydraulic pressure, completing the unloading process quickly and hygienically. The rear cover closes securely with a hydraulically controlled locking mechanism, eliminating any risk of leakage during transportation.

📐 Body Structure and Capacity Options

The Kademe Hydraulic Compactor Garbage Truck is available in a wide range of body capacities to meet the varying needs of municipalities and private cleaning services. With models offering body volumes from 7 m³ to 22 m³, it delivers customized waste management solutions. The compaction ratio typically ranges from 1:3 to 1:5, allowing bulky waste to be compressed into a smaller volume. This reduces the frequency of transport cycles and provides significant savings in time and operational costs.

The body is constructed from high-strength ST-52 steel. Depending on the model, the thickness of the side and bottom plates ranges between 4 and 6 mm, providing durability and resistance against demanding field conditions. The exterior surfaces are coated with electrostatic paint, offering both corrosion resistance and an aesthetically clean finish.

Thanks to its inwardly sloped interior, the body ensures smooth waste flow during compaction. The compactor panel transfers the waste accumulated in the rear chamber into the main body, enabling maximum space utilization. All movements are powered by the hydraulic system and can be controlled precisely via the operator panel, ensuring efficient and safe operation throughout the collection process.

🔧 Optional Equipment

The Kademe Hydraulic Compactor Garbage Truck can be equipped with a variety of optional components tailored to different user needs. These enhancements enable the vehicle to perform optimally under varying geographic conditions, waste types, and operational scenarios.

Rear Automatic Lift for Waste Containers

Enables the automatic lifting and emptying of 120, 240, 360, 770, and 1100-liter containers in compliance with international standards. This feature provides an ergonomic and safe solution while significantly saving time during operations.

Side Container Lifting System

Allows waste containers to be lifted from the right side, especially useful in narrow streets. It is ideal for municipalities with specific city planning or traffic direction requirements.

High-Pressure Washing System

An integrated washing unit with 100–150 bar pressure can be installed on the truck. It ensures efficient cleaning of both the compaction chamber and waste containers, greatly improving hygiene and odor control.

Rear View Camera and Monitor

For enhanced operator safety, a rear camera system can be installed. The in-cabin monitor allows for safe and precise maneuvering during reversing and waste collection operations.

LED Warning Lights and Flashers

LED lighting systems improve visibility while the vehicle is in operation or transit. This ensures increased safety during night-time or low-visibility conditions.

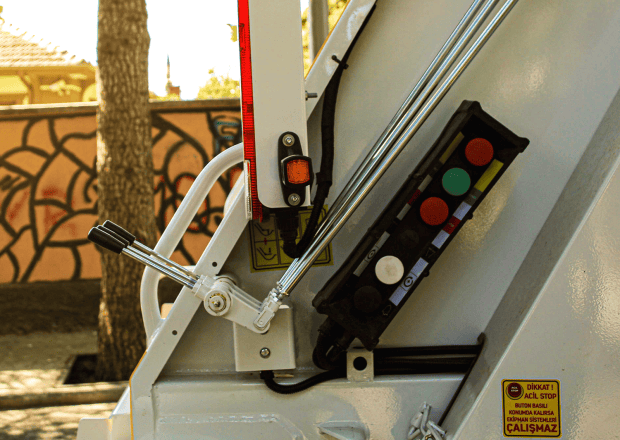

Remote-Controlled System Operation

A remote control unit allows the operator to manage the rear door, compaction mechanism, or lifting system from outside the vehicle, offering greater flexibility and convenience in the field.

Recyclable Waste Compartment

A compartmentalized body enables separate collection of different types of waste, supporting recycling efforts. This option is especially favored in areas with high environmental sensitivity.

🌍 Areas of Use

These trucks are widely used by metropolitan and district municipalities, cleaning service companies, organized industrial zones, and large campuses. They also offer an effective waste collection solution along highways, in airports, resort areas, and expansive open spaces.

Thanks to their high capacity, powerful compaction system, and fast discharge capabilities, these vehicles are ideal for both daily household waste collection and specialized industrial cleaning operations. Their leak-proof design and controlled discharge systems ensure an environmentally friendly and hygienic waste management process.

✅ Why Choose Kademe Hydraulic Compactor Garbage Truck?

Engineered by Kademe, this vehicle stands out for its durability and efficiency. Built with high-strength materials, it ensures long-term use with minimal risk of breakdowns, low maintenance costs, and high operational productivity. The wide range of capacity options from 7 m³ to 22 m³ offers flexibility tailored to the population density and waste generation volume of different regions.

Its advanced hydraulic system enables fast, safe, and user-friendly compaction and discharge operations. With a compaction cycle time of 20 to 35 seconds and a controlled rear door mechanism, time loss is minimized. The superior sealing features prevent the leakage of liquid waste, ensuring an environmentally responsible collection process.

Models with integrated high-pressure washing systems facilitate vehicle hygiene. The in-cabin control panel gives the operator complete command over the system, offering ergonomic and safe operation for both drivers and maintenance personnel.